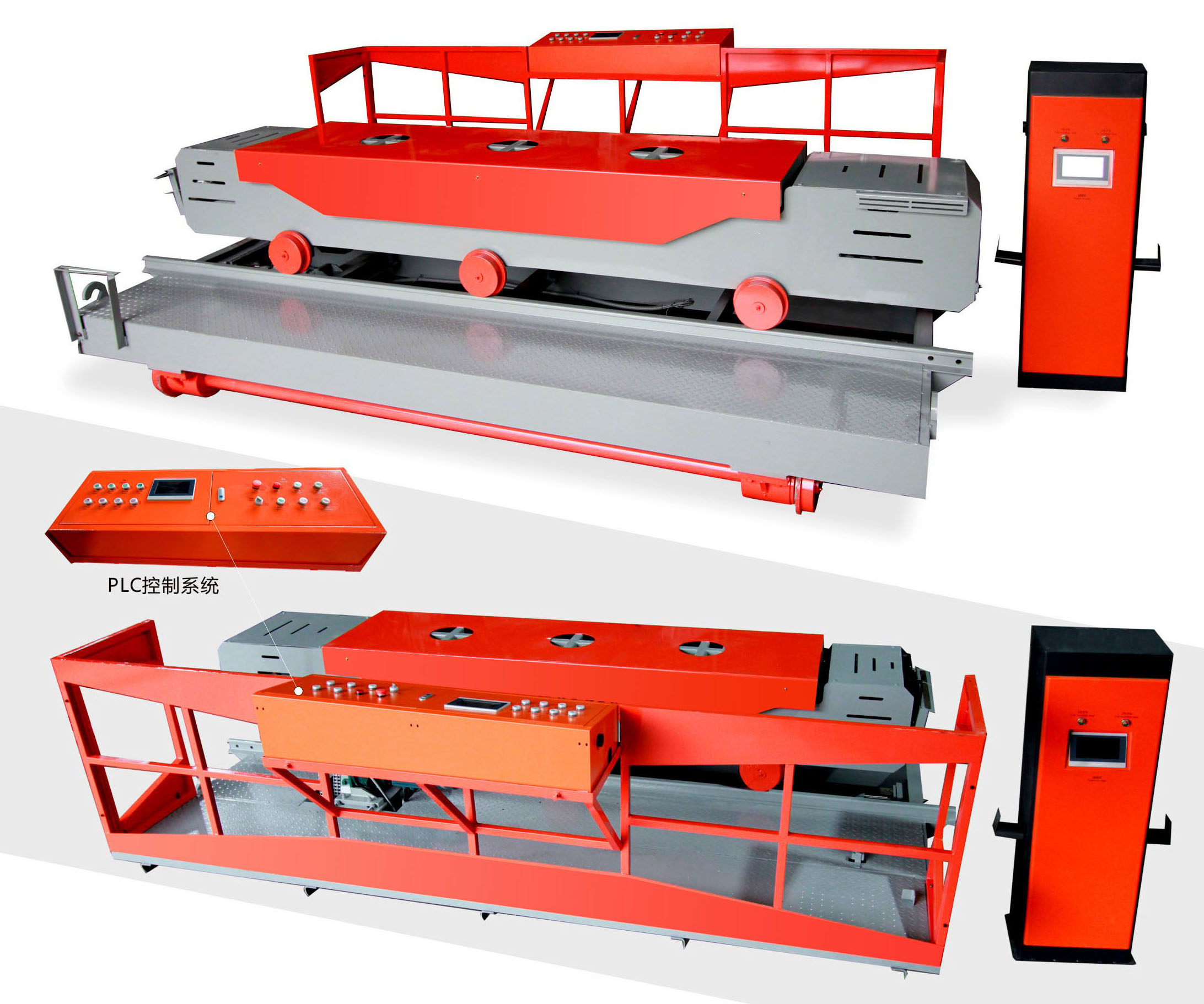

The automatic line for handling and maintenance solves the labor and fuel consumption problems of forklift truck transfer in the follow-up process of the simple block brick production line. It is seamlessly connected with the simple block production line and the intelligent code brick machine to form the whole process of block brick forming, maintenance, and packaging production machinery automation. , to realize intelligent brick making, the mother ferry is positioned by encoder transmission, and the transport trolley enters and exits the kiln, thereby realizing steam curing.

TECHNICAL SPECIFICATIONS

|

Gross weight |

3T |

|

Total power |

12Kw |

|

Maximum load |

~5T |

|

Operation cycle |

150-240s |

1. Driven by DC motor, it has huge starting force and strong overload capacity.

2. The ferry encoder drives the gear rack, and the positioning is accurate.

3. Lithium battery power supply, the track does not need insulation, and the construction and maintenance are convenient.

4. Intelligent fast charging machine, when the battery is low, it will automatically charge at the designated location.

5. A single ferry can carry multiple transport sub-carts to realize the same ferry in and out of the kiln.

Leave A Message

Leave A Message